CNC Burning machines

Our burning machines are compact, advanced and high effecient CNC plasma burning machines for thermal cutting of electrically conductive materials.

During the manufacturing, great emphasis is given on usage of quality materials and components from prestigious world-renowned manufacturers while also maintaining favorable price of the final product.

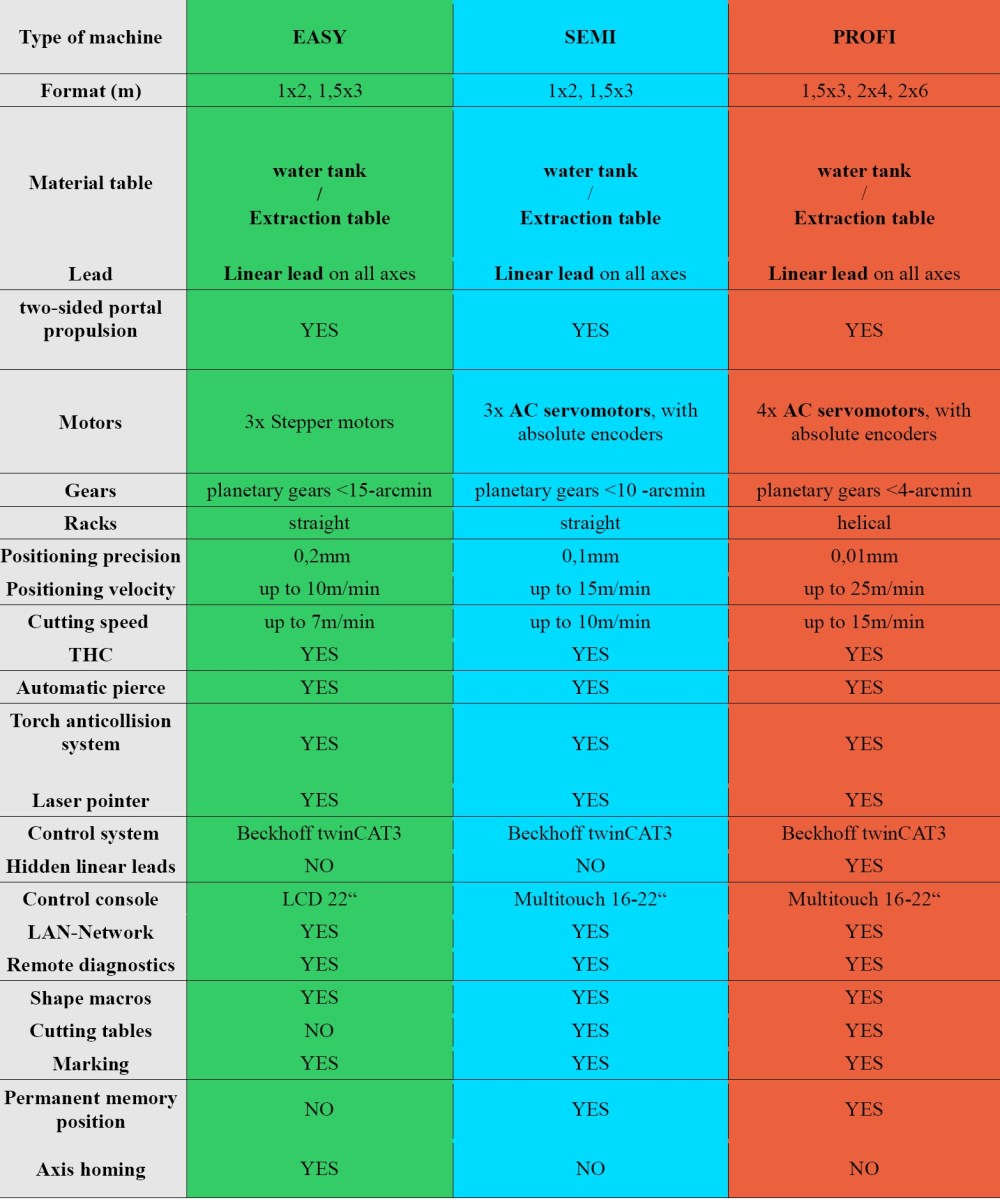

Machine can be manufactured in three different variants according to customers requirements - EASY, SEMI or PROFI.

Our machines are best suited for light to mid size manufacturing plants.

EASY Variant

- Compact construction

- Massive welded frame

- Dimensions of the cutting table are 1x2m - 1.5x3m

- Cutting table - water tank (grate is submerged in the water without air suction)

- - dry grate with ash tray

- Linear lead on all axes for more solid and precise movement

- two-sided portal propulsion

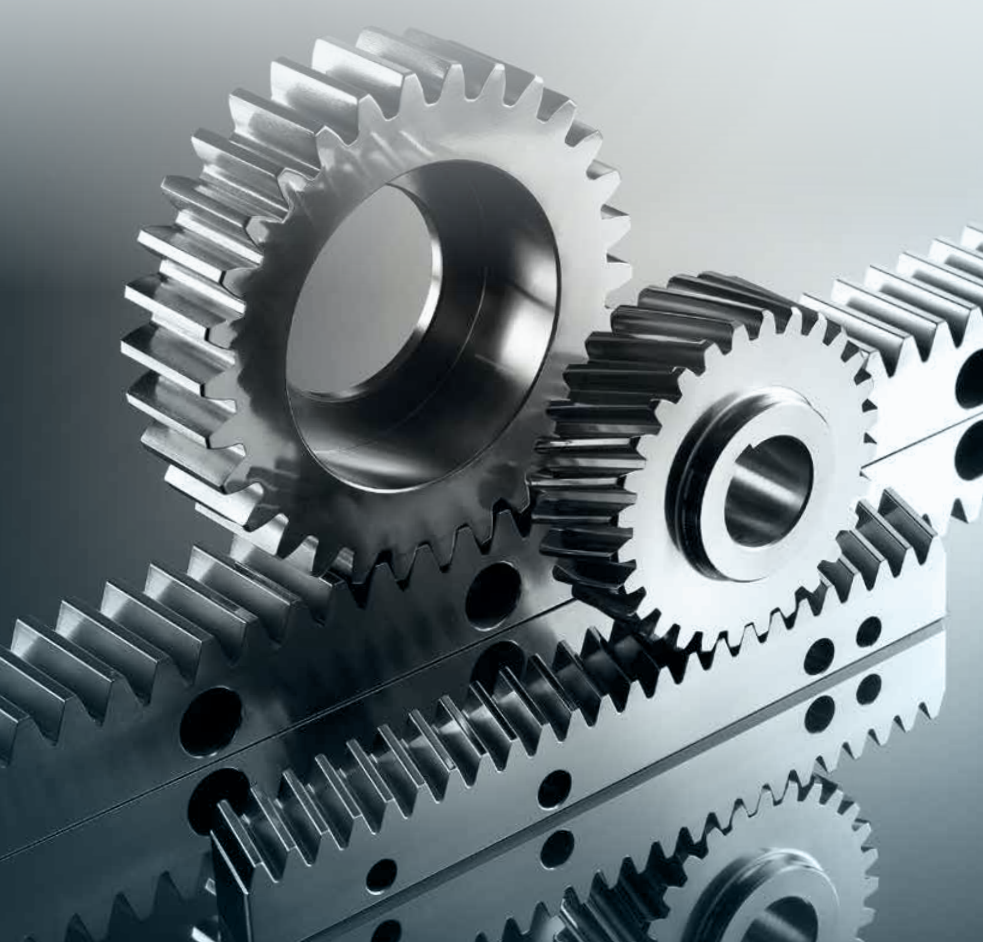

- 3x Stepper motors with planetary gears and rack and pinions are used for propulsion

- Positioning precision of 0.2mm

- Positioning velocity up to 10m/min

- Cutting speed up to 7m/min

- Grate made from steel lamellas submerged in water table(no need for fume extraction)

- The THC technology for automatic Torch Height Control

- Laser Pointer - torch position indicator

- Torch anticollision system

- Control console with up to 24" display size operator panel

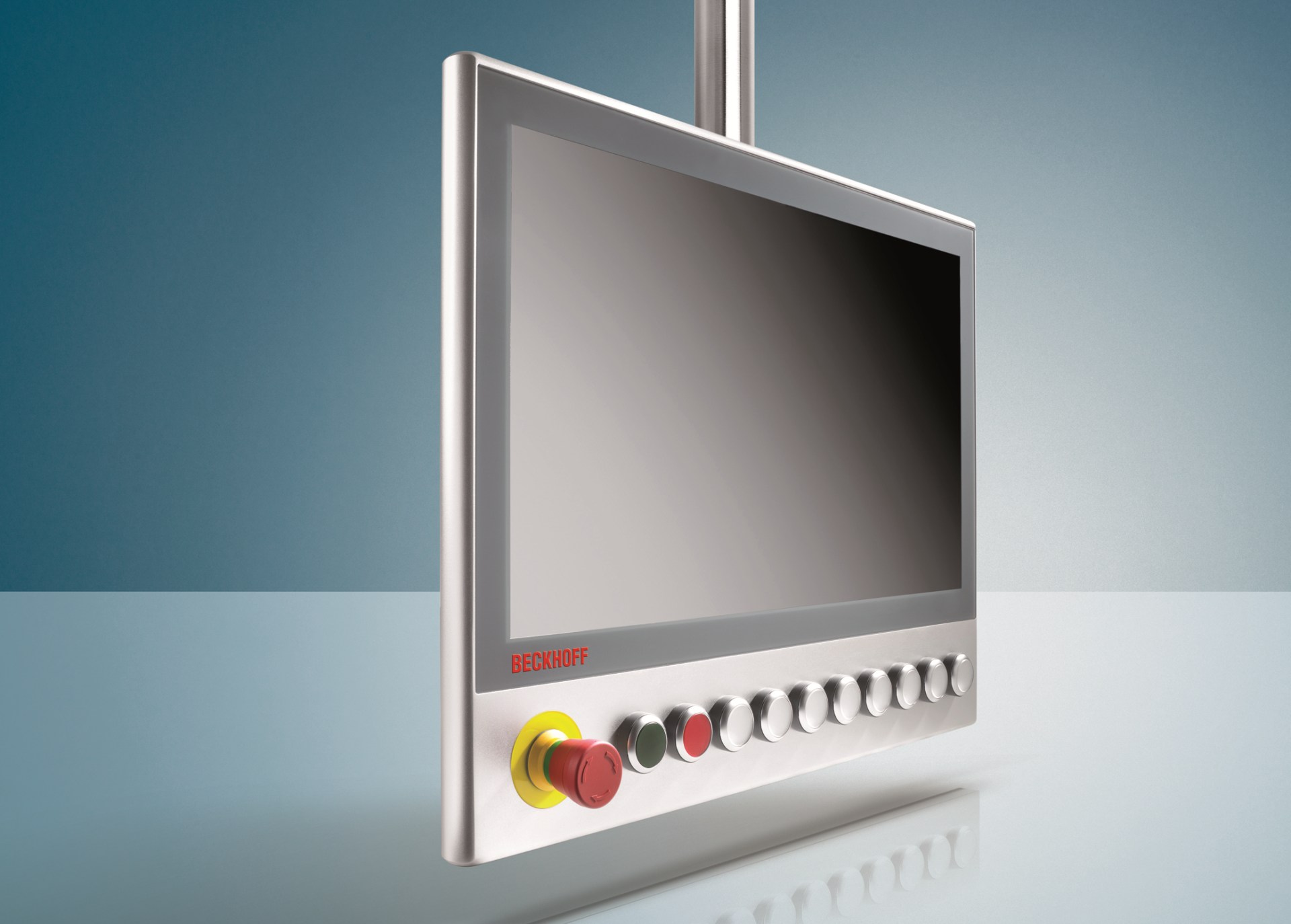

- Industrial Embedded PLC/PLC Beckhoff

- Beckhoff TwinCAT 3 Control system

- 2D CAD for creating geometry

- Simple programming using the preset shape database

- Advanced data collecting system for diagnosis

- LAN network connection support

SEMI Variant

- Compact construction

- Massive welded frame

- Dimensions of the cutting table are 1x2m - 1.5x3m

- Cutting table - water tank (grate is submerged in the water without air suction)

- - section table with electronically controlled valves prepared for use with suction

- Linear lead on all axes for more solid and precise movement

- two-sided portal propulsion

- 3x AC servomotors with absolute encoders

- anti-backlash planetary gears

- Positioning precision of 0.1mm

- Positioning velocity up to 15m/min

- Cutting speed up to 10m/min

- The THC technology for automatic Torch Height Control

- Laser Pointer - torch position indicator

- Torch anticollision system

- Control console with fully integrated industrial multi-touch panel up to 19" display size

- Industrial Embedded PLC/PLC Beckhoff

- Beckhoff TwinCAT 3 Control system

- 2D CAD for creating geometry

- Simple programming using the preset shape database

- Advanced data collection system for diagnostics

- Technology tables

- LAN network connection support

PROFI Variant

- Compact construction

- Massive welded frame

- Dimensions of the cutting table are 1x2m - 2x6m

- Cutting table - water tank (grate is submerged in the water without air suction)

- - section table with electronically controlled valves prepared for use with suction

- Linear lead on all axes for more solid and precise movement

- two-sided portal propulsion

- 4x Effecient AC servomotors with absolute encoders

- Anti-backlash planetary gears, helical rack and pinions

- Positioning precision of 0.01mm

- Positioning velocity up to 25m/min

- Cutting speed up to 15m/min

- The THC technology for automatic Torch Height Control

- Laser Pointer - torch position indicator

- Torch anticollision system

- Control console with fully integrated industrial multi-touch panel up to 19" display size

- Industrial Embedded PLC/PLC Beckhoff

- Beckhoff TwinCAT 3 Control system

- 2D CAD for creating geometry

- Simple programming using the preset shape database

- Advanced data collection system for diagnostics

- Simple programming using the preset shape database

- LAN network connection support

Accesories

- We can supply plasma aggregates made by renowned producers(Cebora, Thermal Dynamics, MAHE, Hyperthem, Kjellberg) with machine torches

- CAD/CAM software for creating the burned part geometry and generating G-code

- Water table - made from alluminum steel with grate submerged in the water. Largely reduces the amount of fumes and thermal deformation of burned steel.

- Extraction table with sectional extraction

- Suction units with filtration

BENCHMARK TABLE